Um, what????

Yeah…. I sawed a lithium battery in half. With zero fires. Pretty insane. I’m basically a ballr.

The need for sawing a battery in half arose while working on the electric moped. FSAE had several 1.6kWh packs which had weird issues, namely that they *occasionally* would short out to their cooling plates. Not hard shorts, just a few hundred kohms- but this is enough that they would slowly discharge, and more importantly, fail the rigorous isolation tests in FSAE rules. Therefore, these packs were not suitable for racecar duty, which meant that they were generously donated to the slums of MITERS.

Despite the shorting problems, the cells in these packs are really good cells which are barely cycled. Unfortunately, these packs are somewhat of a strange aspect ratio. They are only 60V but have 27AH of capacity. I could have opted to build some other pack out of A123s for the moped, but these packs are really, really good, incorporating features like fused busbars and temperature sensors on top of very high quality cells. Ultimately these packs were too good to not use. A few options existed for converting them to useful moped battery, which ideally needs to be at least 200V.

- Somehow dissolve the epoxy out of the packs and reuse the cells.

- Somehow re-terminate the pack to make it into a 180V pack.

- Get good at power conversion- build the infamous boost converter!

Boost converters are notorious for exploding at MITERS. But, they are cool and posed an interesting challenge, so I decided to go with option 3.

The original battery plan involved a single moped pack and a 4x voltage booster, for a final bus voltage of 240V. Geometrically, this fit pretty well within the moped.

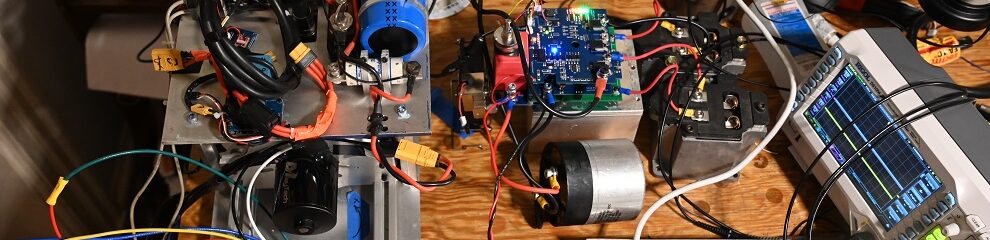

After looking at this setup for a while I realized it might not actually be enough battery. The electric bike does 30 Wh/mile, and at higher speeds the moped will probably need about 40-50 Wh/mile. With only a single 1.6 kWh pack, 50 Wh/mile only results in a weak 32 miles of range. Additionally, I looked longingly at the pile of FSAE batteries destined for the trash, and felt I needed to “save them”. So I came up with option 2, which uses a second battery to boost voltage a bit and a significantly smaller voltage doubler booster. This solution saves money, is more efficient, and will have longer range.

This plan was bad. A full battery wouldn’t fit in front of the motor without hitting the front wheel, so it would need to be sawed in half. Bring in the bomb squad. Let me repeat: I would need to saw a lithium battery in half. Any person with access to the internet knows that this is a recipe for an extremely large fire. Even the smallest puncture of a cell can lead to a fire, not to mention sawing one in half. However, it was not as bad as it could have been. The pack I wished to saw was an 18650 pack potted in epoxy, so it was hypothetically possible to saw around the individual cells without compromising the whole pack. Hypothetically.

So, onward!!!

I located a battery from the pile which was already compromised. This battery had a fault on one cell, so the row that cell was in had been cut up. Also, the bridges between the cells were cut for whatever reason.

It turned out that this pack was perfect for what I needed. First of all, the connections between the cells were cut, so this battery presented no high voltage hazard, and could not be shorted as easily. The compromised cell was in the 11th row, meaning that a 10S pack would be left if the battery was cut at that location. Therefore, with the other battery inline for a total of 26S, the total pack voltage would be about 100 volts, easily doubled to a happy 200V. For big high speed power, this could even be tripled for a bus voltage of 300V, but with my gear ratio that would push base speed up past 50, which is overkill for daily driving. So, 200V it is. Also, just a single doubler is easy to make, easy to package, and very efficient.

First up, I ripped off the baseplate of the battery. All the issues of this battery stemmed from the thin epoxy bond between the bottom of the cells and the baseplate. Hypothetically, removing the baseplate should simply remove the problem! Removal of the baseplate was accomplished with large effort through a combination of slow rocking, prying, and yelling.

The battery was placed on the chopping block.

The original plan was to use a very fine coping saw to saw in between the cells. However, the epoxy proved to be incredibly abrasive and would dull the saw after just a few strokes. So, time for plan B….. saw straight through the cells themselves, which are softer than the epoxy.

What?

Yep. This battery is worth destroying several cells to use. One cell in that row was already compromised anyways. But, how to saw through cells? Cells usually explode when you do this, because all the stored energy in the cell is released at once when the cell shorts. I just soldered some resistors to the cells and let them discharge overnight. In the morning I resumed sawing. I first sawed into the edge cell. Sawing the cell proved to be very bad, but with some amount of force the cell was excavated.

I then decided to try drill the cells. This worked great. It was a little challenging but was eventually accomplished. When all the cell cores were removed I then sawed through the thin layer of epoxy between the cells.

Once it was mostly sawed I just cracked the rest.

Less bad than I was expecting!! Just one night of cell discharging and one night of drilling and sawing.

The “freed” 10s pack.

In summary: this pack had a dead cell anyways, and was headed for the trash. By careful drilling and sawing, the bomb was diffused and this pack will hopefully propel me on my moped. Stay tuned for more moped shenanigans!!!