Not much in this post, but its definitely worth mentioning if any readers care to make dollys for their machine tools.

A core tenet of the austinshop final plan is to have the surface grinder on wheels such that it can be wheeled outside to use, to protect the shop from being covered in grinding dust. To do this I need some way of wheeling it. And the surface grinder isn’t light, so it needs to be extremely strong.

I started with the door bits because they are nice, strong wood about the right size (read later post to see where those came from). I attached the casters with huge lag bolts, probably 3/8″ OD beeg boi bolts. Should be enough to keep the wheels from pulling out.

Using some amount of crowbar-ing, I lifted the surface grinder and supported it with some 2x4s while I removed the skids:

Then I lag bolted the dolly pieces on.

Success. It actually wheels really well on the epoxy floor. On asphalt though, different story.

Once the grinder exits the garage, it does get very difficult to roll, which is annoying. Luckily, I won’t be using this tool that often, so that is ok. When I roll it out of the garage, I make sure to roll it in the direction that it is less likely to tip over, because its pretty tippy on the garage ramp (lol).

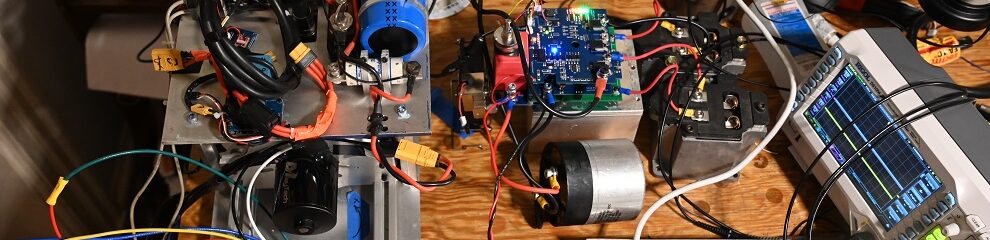

I gave the grinder a brief run to see how it worked. I’d only really used a surface grinder once before, so it was kind of a cool experience. This one also has no autofeed, which is kind of a pain in the butt (or wrist actually). Definitely begging for some big brushless autofeed. Anyways, it was pretty cool to use this one though. The part I made actually turned out quite shiny, which was surprising- it had a high shinyness to effort ratio.

Definitely I should have used bigger casters for this, as I think these ones are only rated for 250lbs and this grinder is probably at least 500lbs. When going over rough ground the load basically is concentrated on a diagonal pair so I am definitely pushing the rated load for these 3″ casters. And it doesn’t even wheel that well over bumps- definitely wish the wheels were bigger. Also, the front and back pieces of dolly were flexing away from each other, giving the dolly a sagging look. I had to add a cross member to stop this. I definitely would recommend adding cross members to future dollies.

Also, I used my work’s mill to mill down the lathe drawer a bit. I then put Teflon tape on the bottom of the drawer. and WOW- what a difference the Teflon tape makes. The drawer slides like butter, even when FULL of carbide!

Anyways, another ramble! Time to write another….