Over the past four years, automotive hybrid air conditioners have been a wonderful source for rotors and stators. All the automotive components are automotive quality, yet purchasable at junkyard prices. So far, all the air conditioners we’ve dissasembled have been of the IPM variety. We’re not exactly sure why, but we believe this is because the magnets can be straight instead of curved, reducing magnet costs. Additionally, the rotor can be constructed using less magnet per unit torque, again reducing cost. Either way, IPMs are cool, so let’s get started.

So far, I’ve disassembled four different air conditioner units, all made by Denso: the ES14C, the ES18C, the ES27C, and the elusive ES34C. The ‘ES’ stands for ‘electric scroll’ and the number corresponds to how many CCs of pumping they do (1.8 to 3.4CC I guess?). This is the first non-Denso unit we have got our hands on. We managed to find this one for cheap on Ebay as it had a damaged connector.

The unit we will be deconstructing is the ‘Hanon HES 33’, I presume which is 3.3 CC’s of pumping. Right off the bat, it’s clearly much bigger than the previous unit’s I’ve seen. Cans of beans for scale.

The valves. This is as normal.

The beautiful scroll as normal. Can of beans for scale.

Moment of truth…..

Rotor was a bit smaller than anticipated. But, looks about right.

The rotor was confirmed to be the normal 6 magnet deal.

The stator had a surprise. All the Denso’s I’ve seen are a 6 magnet rotor paired with a distributed wound 18 tooth stator. However, this stator had 27 teeth. My guess is that this is some distributed-wound trick to reduce harmonics. Looking at the winds here, it is clear that the wind on the right encircles four teeth, while the wind on the left only encircles three teeth. Luckily the laminations are quite thin, although nice thin laminations seem to be standard across all the air conditioners.

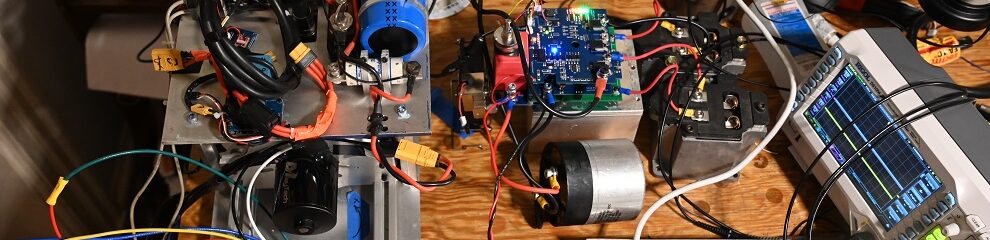

Next up was the electronics stack. Unfortunately, the PCB was unremovable, as my guess is that the IGBTs were screwed down and then the PCB soldered on. It is interesting to note that this driver uses discrete devices rather than the normal integrated IGBT brick found on most of the more modern air conditioners. Additionally, this device had a most interesting input filter, which I’ve never seen in real life. It appears to be two inductors with a common mode choke as well, which prevent current ripple from getting onto the DC bus. The normal approach is “big ripple is fine, no one cares” but I guess for some reason they decided to care here. Also visible is some sort of isolated CAN deal for the input at the top of the image. It seems that most of the high voltage areas are potted in a liberal amount of high voltage goo.

One interesting feature of this air conditioner is that it is a stack of castings rather than the usual Denso deal where there is just one main casting plus some covers. I guess in the Denso units the scroll sits inside another casting, so the total number of parts is comparable. Here, the fixed scroll is part of the stack, rather than a component that sits inside another casting.

The same components except inverted.

Stator extraction. Luckily, this casting was short enough to just be clamped in my mill, so I milled some slots into it and pried it open. Some chips always get into the stator when I do this, but they are usually pretty easy to remove with the vacuum, as the stator isn’t magnetic.

The rotor and stator with beans for scale. The stator OD is 96mm and the stack height is 46mm. It does look quite well wound.

I re-assembled the rotor and stator for some KV measurements. I used the good ol “grab the pin in a drill and let er wub” technique.

The KV measured out to be 35.5 (elec. period = 46ms, Vpk = 12.25v), or 0.269 Nm/amp. This would give a no-load speed of 12.4k RPM at 350V. Probably this motor is optimized to run about 8000 RPM and the additional volts are lost to resistance and inductance. The line to line resistance was measured to be 0.465 ohms, which is about expected for a stator of this size. I’d estimate this stator is good for about 50 phase amps peak, which would probably give you somewhere around 12-15 kW peak at 400V. She juicy

Also worth noting is how wonderfully sinusoidal this motor is. The other air conditioners are nowhere near this good, having significantly higher harmonic content. Usually the 5th harmonic gets you pretty badly on the air conditioners, but this seems to have very low low freq content. The small harmonic visible here is a 19th harmonic, but that is high enough frequency that no one cares.

For reference, here is a scope shot of another air conditioner, which has a harmonic content of ‘big’:

More motor science to come…….