Hey all, this project has been a long time in the making. Here goes.

Over my senior year, I built the electric bike, which somehow turned out to be awesome. I estimate it has been over a thousand miles, and it has literally never left me stranded- not once. It’s small enough to fit on the commuter rail, yet produces enough torque to literally do a backflip. It is the perfect fun city ride. Yet, the electric bike does leave some things to be desired. Over the summer of 2019, I decided on some features that I wanted in a new vehicle:

- Suspension. A lack of suspension is OK for short distance, and in fact even beneficial because it makes the bike simpler and lighter. However, after 20 miles of no suspension, it really starts to get painful.

- 50 mile range. The bike’s 20 miles is enough to explore the Boston area, but is runs on fumes by the time it reaches Lincoln. Western Mass is out of reach.

- Higher speeds. The electric bike will hit 50 (just barely), but it is terrifying. It comfortably cruises around 25. I would like my new vehicle to cruise at 35 ish to keep up with traffic.

- Waterproofing. I want to be able to ride though puddles, a feature the electric bike does not have.Waterproofing is a big headache: EVERYTHING must be enclosed, you need o-ringed connectors, bearings must be sealed, etc. But this is necessary for a daily driver vehicle.

- Looks dank. I want this thing to look sciencey. Electric bike looks like a dumpster fire, not sleek.

With these requirements laid out, I looked for a donor frame. The strategy of “find a frame and attach motor” used in the electric bike worked out really well in the electric bike, as I am not really interested in making frames. Also, it turns out that you can get a really, really well made frame for only several dollars. Bike frames were more or less figured out in 1900. Several options existed for a frame: Mountain bike, Motorcycle, or Moped. I ultimately settled on moped for a few reasons:

- Bike frames are not designed to take motors. Either you end up with a motor tumor mid drive thing or a motor tumor on the side.

- I wanted something that was a little heavier than a bike, for a slightly smoother ride at higher speeds.

- Motorcycles are scary. A motorcycle is happiest doing 80+ on the highway, which I am not interested in doing- I only want to do 35!

- Additionally, motorcycles are really big and heavy- most motorcycles are about 500 lbs if not more. The motor and battery requirements become fairly substantial and expensive at motorcycle power levels.

A moped seemed to be the correct choice, as it is designed to take a motor and is not a motorcycle. So, onto the craigslist!!! I looked for a moped with a tube frame. A lot of mopeds have stamped frames with integrated gas tanks. I find the stamped frames very ugly and also I do not need the gas tank.

Eventually I found exactly what I was looking for- a Kreidler MP-19 with a seized motor, for $150. I went all the way out to western mass to pick it up.

I sold the gas tank and the motor and recouped $50, so all in all ended up with it all for $100. I cleaned it up as best as I could.

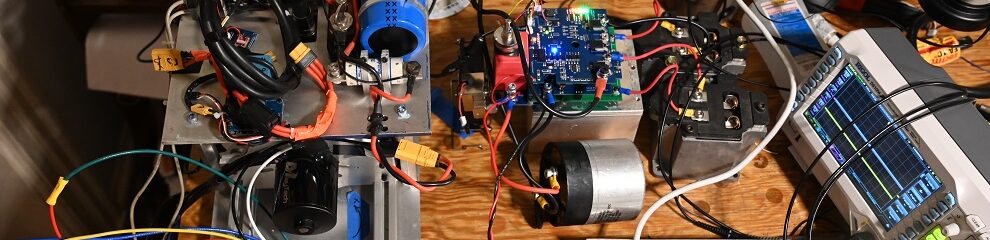

Next up was coming up with a vague plan for the battery and motor. The motor I was interested in using was a bar wound motor, the 2007 Toyota Camry A/C compressor motor. This motor has a 30% longer stator stack than the Prius motor and a flux linkage about 10% higher, but has only 2/3 the resistance because it is bar wound. Therefore the motor constant is a full 35% higher!! I estimate this motor is good for about 10 Nm peak. This motor demands a bus voltage of at least 200 V for good performance.

This left choosing the battery, which proved to be slightly more challenging. On the electric bike, the perfect pack made of Greenworks packs sort of fell into my lap. The electric bike uses four 4Ah 40V packs in series for a total of 160V and 600Wh. For the moped, I needed to the pack to be substantially larger, because I would like longer range at higher sustained speeds on a larger and heavier vehicle. MIT’s FSAE team luckily had a few barely used 16S9P packs laying around, so I snapped them up. These packs had some weird issues where they would short to their aluminum cooling plates, so we used big force to rip the cooling plates off. Problem solved! My average power draw is low enough that these packs will not need any special cooling.

The original plan was to run one of these packs and a 4x booster for a final bus voltage of 240V. This plan was not ideal however, as it is difficult to make a 4x doubler with high efficiency, and the pack was still kind of small at only 1.6kWh. After looking sadly at the rest of the FSAE batteries which were destined for the trash I eventually revised my plans to run 1.6 of these FSAE modules for a total of 26S 9P followed by just a doubler, for a final bus voltage of 200 V. While on the low end, this is fine for what I need. This plan required sawing a battery in half, but surprisingly this was accomplished without high difficulty.

At the moment, the project is more or less on hold due to coronavirus. I have been working on getting some little OLED screens working, which will eventually become the dashboard. These little OLED screens are nice, but take about 100 ms to write a whole frame buffer because they talk over I2C which is extremely slow. Getting these to work on a Nucleo and not bog everything down requires extensive utilization of the DMA, which has been a cool coding experience.

Stay tuned!